Product Details

|

Name |

Machining and Turning Milling Steel Parts |

|

Materials |

Brass, Stainless Steel, Steel, Aluminum etc. |

|

Surface Treatment |

Anodized, Plating and others |

|

Process |

CNC Turning Milling |

|

Tolerance |

ISO 2768-m |

Introduction

Aviation industry is a national strategic industry that drives the development of national economy and cutting-edge technology and consolidates national defense construction. The particularity of the service occasions of aviation parts constantly puts forward high requirements for their manufacturing quality, so strict control of product surface quality has become the criterion of aviation manufacturing industry.

A considerable part of aerospace materials are hard-to-machine metal materials, and the cutting force and workpiece temperature during the cutting process, especially in the finishing stage, will directly affect the surface quality of the workpiece. However, the machinability of difficult-to-machine materials is poor, and the force and thermal load during the cutting process have a strong impact on the surface quality of the parts. Therefore, accurate prediction of the cutting force and workpiece temperature has far-reaching significance for ensuring the machining quality and service performance of key aerospace components.

For some special-shaped rotary parts with complex shapes and high precision requirements in aviation, aerospace, shipbuilding, military, and civil industries, turning and milling can complete all or most of the processes in one-time clamping. It can not only ensure the accuracy, but also improve the efficiency and reduce the cost.

*Machining and Turning Milling Steel Parts

HC-Rapidprototype Advantage and Service

- Cutting-edge technology: Advanced CNC machining centers and turning equipment: Our facility is equipped with the latest CNC machining centers and turning equipment, leveraging cutting - edge technology to achieve unparalleled precision and efficiency in manufacturing complex parts.

- Experienced team: Skilled engineers and technicians with years of industry expertise: Comprising seasoned engineers and technicians, our team boasts extensive industry experience. Their in - depth knowledge ensures top - notch craftsmanship and innovative solutions for every project.

- Quality assurance: Rigorous quality control processes and ISO 9001 certification: We implement strict quality control measures at every production stage, adhering to ISO 9001 standards. This guarantees consistent, high - quality products that meet the most demanding requirements.

- Competitive pricing: Cost-effective solutions without compromising on quality: Through optimized production processes and strategic sourcing, we offer cost - effective solutions. Our pricing remains competitive while maintaining unwavering product quality.

- Fast turnaround: Efficient production and on-time delivery: With streamlined production workflows and effective project management, we ensure rapid turnaround times. Our commitment to on - time delivery means you can rely on us for timely product fulfillment.

Product Characteristics

Our Machining and Turning Milling Steel Parts offer:

- Exceptional dimensional accuracy

- Consistent quality across large production runs

- Excellent surface finish and aesthetics

- High durability and performance in demanding applications

Production Process

1. Material selection and preparation

2. CNC programming and setup

3. Machining and turning operations

4. Quality inspection and measurement

5. Post-processing (if required)

6. Final quality control and packaging

Development trend of turning and milling compound machine tools

1. Higher process range

More process integration can be achieved by adding special function modules.

2. Higher efficiency

Equipped with functions such as dual power heads, dual spindles, and dual tool holders to achieve simultaneous multi-tool processing and improve efficiency.

3. Large-scale

Since large parts are generally complex in structure, require many parts and processes to be processed, and are time-consuming and labor-intensive in installation and positioning, one of the main advantages of turning-milling composite machining is to reduce the number of parts in multi-process and multi-process processing. Reinstallation adjustment and clamping time are less, so it is more advantageous to use a turn-mill center for compound machining.

4. Structural modularity and function can be quickly reorganized

The function of the five-axis turning and milling center can be quickly reorganized is an important condition for it to quickly respond to market demands and seize the market, and the structural modularity is the basis for the rapid reorganization of the five-axis turning and milling center functions.

Applications

Our precision-engineered components find applications in various industries:

- Automotive: Engine components, transmission parts, and chassis elements

- Aerospace: Structural components and critical system parts

- Industrial equipment: Machine parts, hydraulic components, and tooling

- Medical devices: Surgical instruments and implant components

Shipment

FAQs

Q: How about your delivery terms?

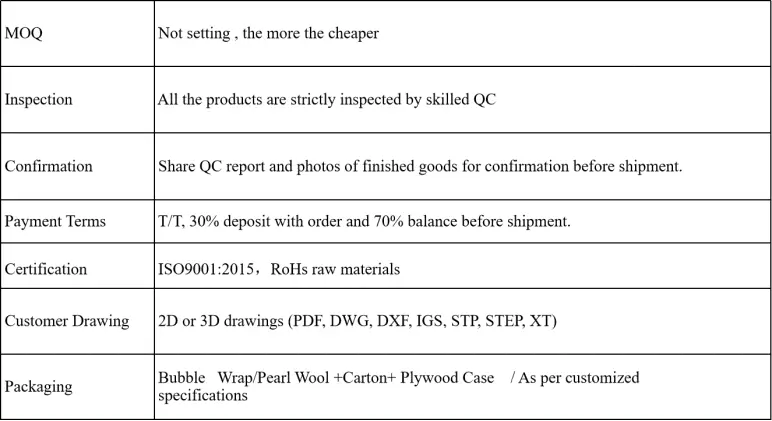

A: For details please refer to below table.

YOU MAY LIKE

_1744788508965.png)