Product Details:

|

Name |

CNC Turning and Milling Machining parts |

|

Quality control |

100% QC quality inspection before delivery, can provide quality inspection form. |

|

Surface Treatment |

Zinc plating, Sand blasting, Brushing & Polishing etc. |

|

Sale market |

Europe, America etc. |

|

Service |

We will answer your email or inquiry within 12 hours |

|

Application |

Furniture hardware, electronic hardware, construction machinery parts, metal processing machinery etc. |

|

MOQ |

Accept small order, Feel free to contact us for further inquiry. |

Introduction:

HC-Rapid prototype is a professional precision machining& Metal Fabrication factory located in Shenzhen, CHINA and specialize in this field for more than 10 years. We now have CNC lathe , CNC milling machine(sophisticated machining center), CNC Turning and Milling Machining part and other EDM equipment ,3D printing and vacuum casting device etc.

With these machines and experienced technicians, we are able to provide strong guarantee for precision parts. We strive to exceed our customers' expectation in all aspects of product manufacturing process. keep adopting advanced production facilities to improve efficiency and ensure high and stable quality, and further reduce the production cost.

Besides, we have long term cooperated partners on sheet metal, 3D printing ,vacuum casting and EDM discharge machining as well. We can offer a one-stop service to fulfill your whole project. Our purpose is to help millions of buyers for custom CNC machining parts to do business easily.

Welcome to discuss your ideas with our technical team.

Key Characteristics of Our CNC Machining Parts:

- Precision-Driven: Ideal for aerospace components or medical implants requiring micron-level accuracy. Our cutting-edge manufacturing technologies and strict quality control measures enable us to achieve micron-level precision, ensuring that aerospace components can withstand extreme conditions and medical implants meet the highest safety and performance standards.

- Scalable Production: Seamlessly transition from prototyping to bulk orders with no quality gaps. Equipped with advanced production facilities and a well-organized workflow, we can efficiently handle projects of all sizes. Whether it's a single prototype or a large-scale production run, we maintain consistent quality throughout.

- Custom Solutions: Collaborate with our engineers for design optimization or material recommendations. Our experienced engineering team works closely with you to understand your specific requirements. We offer expert advice on design improvements and material selection, tailoring solutions to your unique needs.

Why Choose ShenZhenHuangCheng Technology?

1. Advanced Capabilities for Complex Designs

Our facility houses multi-axis CNC machining centers and 3D printers, enabling us to handle intricate geometries and prototypes. Whether you need small batches or thousands of units, we ensure consistency across every order.

2. End-to-End Cost Efficiency

By sourcing raw materials locally and optimizing workflows, we reduce costs without compromising quality. Our high price-performance ratio makes us a strategic partner for long-term projects.

3. Rapid Turnaround, Every Time

Adhering to “high efficiency, accurate delivery” principles, we meet tight deadlines—ideal for JIT production. Need urgent revisions? Our flexible processes adapt swiftly.

4. Quality Built into Every Step

From CAD/CAM programming to final inspections, our team employs advanced metrology tools and strict quality checks. We minimize rework risks, ensuring parts meet FDA, RoHS, or industry-specific standards.

Applications Across Industries:

- Automotive: Engine components, brackets, and sensor housings.

- Aerospace: Turbine blades, landing gear parts, and structural fittings.

- Medical: Surgical instruments, implantable devices, and diagnostic equipment.

- Energy: Valve bodies, heat exchangers, and drilling components.

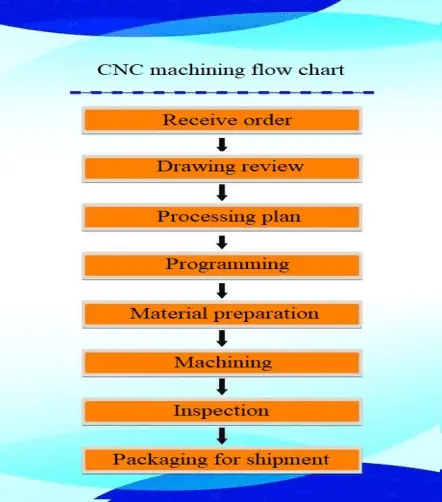

CNC machining process:

CNC Turning and Milling Machining part is machining with CNC machining tools. It is programmed in CNC machining language to control tool feed rate and spindle speed, as well as tool changeover and coolant delivery. CNC machining can process parts with complex shapes that cannot be done by hand. CNC machining technology has been widely promoted, and the general machining flow chart is shown in the figure below.

FAQ:

Q1: Can you make machining parts based on our samples?

A1: Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q2: Is it safe of my drawing and design?

A2: We can sign the NDA with you. All of the customer's drawing only use for the processing and inspection, don't

Copy and show others.

YOU MAY LIKE

_1744788508965.png)