Product Details

|

Product Name: |

OEM Precision Turning and Milling Parts |

|

Material: |

Aluminum, Stainless Steel, Copper or other plastic materials |

|

Finishing |

Anodized(Black, Silver, Purple, Red…) etc. |

|

OEM Drawing |

2D (PDF/ DWG/ DXF) & 3D (IGS/ STP/STEP/XT) |

|

MOQ: |

1PC or more , the more the cheaper |

|

Tolerance: |

+/-0.05mm or refer to ISO 2768-m |

|

Process: |

CNC Turn-mill Compound |

Introduction

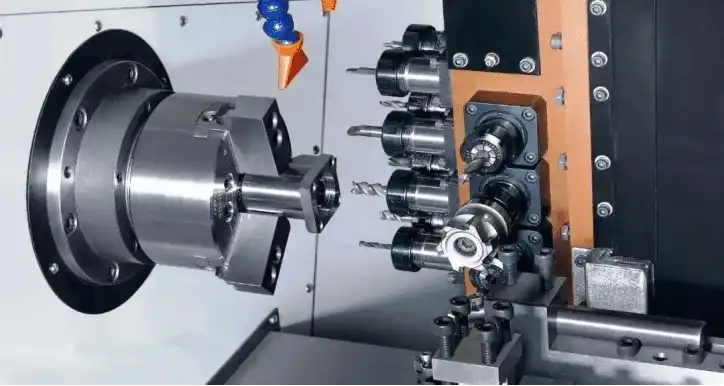

Turn-milling is one of the most popular processing techniques in the world, and it is an advanced manufacturing technology.

Compound machining is to realize several different machining processes on one machine tool. It is the most widely used and the most difficult. The turning and milling compound machining center is equivalent to the compound of a CNC lathe and a machining center.

Compared with the conventional CNC machining process, the outstanding advantages of turning and milling compound machining are mainly reflected in the following aspects:

(1) Shorten the product manufacturing process chain and improve production efficiency.

(2) Reduce the number of clamping and improve the machining accuracy.

(3) Reduce the floor space and reduce the production cost.

*Turning and milling compound machining

Features of Turning and Milling

1. The turning and milling compound machining center uses a high-precision built-in spindle;

2. Free-moving operation panel improves work efficiency;

3. Mainly used for high-speed processing and diversified processing of various small parts and complex parts in mass production;

4. In particular, the slender and complex processes can be processed and formed at one time, and an automatic feeding device can be configured to improve efficiency;

5. Material details: copper, iron, aluminum alloy, stainless steel, Teflon and other materials

*More Precision Turning and Milling Parts for reference

Production Process:

1. CAD/CAM design review

2. Material selection and preparation

3. CNC turning and milling operations

4. Quality inspection and testing

5. Surface treatment (if required)

6. Final inspection and packaging

Applications:

Our OEM Precision Turning and Milling Parts find use in:

- Automotive components

- Aerospace parts

- Medical device manufacturing

- Industrial machinery

- Electronics and telecommunications

Why Choose ShenZhenHuangCheng Technology Co.,Ltd.?

1. Expertise: Years of experience in precision machining

2. Advanced Technology: Latest CNC equipment for optimal results

3. Quality Assurance: Rigorous quality control procedures

4. Flexibility: Adaptable to varying order sizes and specifications

5. Cost-Effectiveness: Competitive pricing without compromising quality

6. Global Reach: International shipping capabilities

Our service and advantages

1. Advanced manufacturing equipment and professional technicians

2. We have a professional service team

3. High quality and pretty surface treatment

4. Te best solutions and competitive price

Remark

1. The packaging according to customer’s requirement.

2. Shipping: Support Express, Sea freight, Land freight and Air freight.

3. Any questions, please kindly contact us. Our team will solve your problem.

FAQ

Q:Do you make customized products based on our design drawings?

A: Yes. Nearly all our products are customized. We are a professional metal fabrication factory with an experienced engineering team to make custom products according to clients' drawings.

Q: Is it safe of my drawing and design?

A: We can sign the NDA with you. All of the customer's drawing only use for the processing and inspection, don't copy and show others.

Q: What is the minimum order quantity for OEM Precision Turning and Milling Parts?

A: We accommodate various order sizes, from single prototypes to large production runs. Contact us for specific details.

Q: Can you provide custom finishes for the parts?

A: Yes, we offer various surface treatments and finishes to meet your requirements.

Q: What is the typical lead time for the products?

A: Lead times vary based on complexity and quantity. We strive for quick turnarounds and will provide an accurate timeline upon receiving your specifications.

YOU MAY LIKE

_1744788508965.png)