Product Details

|

Name: |

OEM Turning and Milling Metal Fabrication Parts |

|

Materials: |

Titanium, Steel |

|

Surface Finish: |

Gold Plated, Anodized |

|

Tolerance: |

Normally +/-0.05mm |

|

Lead Time: |

To Be Negotiated |

Introduction

We are a distinguished precision prototypes manufacturer, boasting over a decade of invaluable experience in the industry. Our journey through these years has been marked by continuous innovation and refinement, enabling us to stay at the forefront of precision manufacturing. Equipped with state-of-the-art high-precision equipment, we possess the tools necessary to execute even the most intricate designs with pinpoint accuracy. Complementing our advanced machinery is our professional technology team, a group of highly skilled engineers and technicians whose expertise spans multiple disciplines. When it comes to production, we offer great flexibility. Whether you provide us with detailed drawings that meticulously outline your specifications or a golden sample that serves as a physical reference, our team will carefully study and analyze the provided materials. Leveraging our experience and cutting-edge capabilities, we will then proceed to craft the final parts that meet and exceed your expectations. We wholeheartedly welcome you to reach out to us. Experience firsthand our warm and dedicated service, as well as our professional and in-depth Q&A sessions. At our company, your trust is not just a transactional element; it is the very driving force that propels us forward, inspiring us to continuously deliver excellence in every project we undertake.

Product Characteristics:

- High precision and dimensional accuracy: Employing advanced manufacturing technologies and state-of-the-art measuring tools, we ensure that each part we produce adheres to strict tolerances. Our meticulous processes guarantee precise cuts and shapes, enabling seamless integration into complex assemblies.

- Excellent surface finish: Through a combination of optimized machining parameters and specialized finishing techniques, we achieve a superior surface quality on all our products. This not only enhances the aesthetic appeal but also improves functionality and reduces the risk of wear and tear.

- Consistent quality across large production runs: Rigorous quality control systems and automated production processes are in place to maintain uniform standards throughout extensive manufacturing batches. Every part, regardless of quantity, meets the same high - level specifications.

- Customizable to your specific requirements: Understanding that one size does not fit all, our team works closely with you to develop tailored solutions. From design modifications to material selection, we can customize products to perfectly match your unique needs.

Production Process:

- Design review and optimization: Our experts analyze designs, identify flaws, and optimize them for efficient and cost - effective production.

- Material selection and sourcing: Based on project needs, we choose suitable materials and source high - quality ones from reliable suppliers.

- CNC programming: Skilled programmers create precise CNC codes, ensuring accurate and smooth machining operations.

- Turning and milling operations: Using advanced machines, we perform turning and milling to shape materials into desired parts.

- Quality inspection and testing: Rigorous checks and tests are conducted to ensure parts meet strict quality standards.

- Surface treatment (if required): When needed, we apply treatments like coating or polishing to enhance part performance and appearance.

- Packaging and shipping: Parts are carefully packaged to prevent damage and shipped promptly with tracking provided.

Applications:

Our OEM turning and milling metal fabrication parts find applications in:

- Automotive components

- Aerospace parts

- Industrial machinery

- Medical devices

- Electronics manufacturing

- Defense equipment

Our Service and Advantages

Comparing to other prototype supplier , we can offer as below list:

1. Competitive Price:

2. Mature business team

3. Considerate service

4. Strict5. The product is packed tightly

6. Comprehensive follow-up by production personnel

*More OEM Turning and Milling Metal Fabrication Parts for review

Delivery

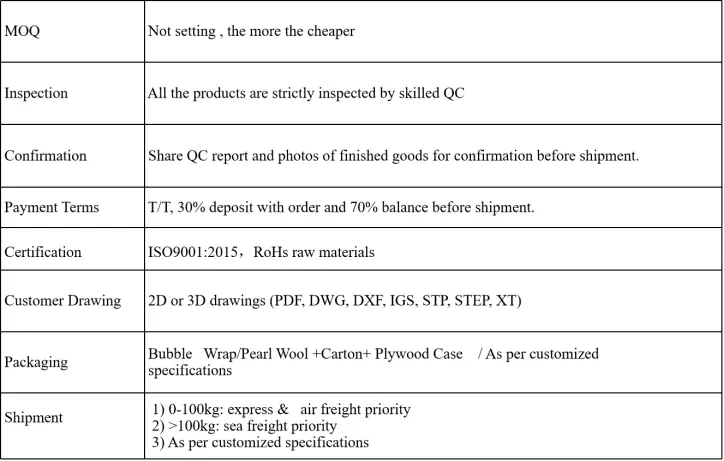

Our delivery terms were listed in below table.

FAQs

Q1: How you guarantee the quality?

A1: Our prototype will be strictly complied with the requirements on drawing. We offer details photos and QC report to let you confirm before shipment.

Q2: Do you provide custom packaging?

A2: Yes, we can do it for you.

YOU MAY LIKE

_1744788508965.png)