Product Parameter

|

Product Name |

Professional Turning and Milling Anodized Parts |

|

Material |

Aluminum, Steel, Bronze etc. |

|

Surface Finish |

Anodizing |

|

Size |

Customized |

|

Drawing |

3D (IGS/ STP/STEP/XT) / 2D (PDF/ DWG/ DXF) |

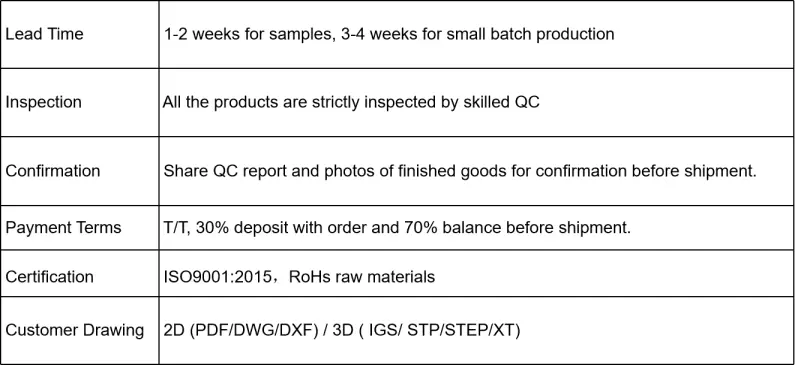

Delivery

For HC-Rapid Prototype delivery terms , please refer to below table for details.

Introduction

Currently , Along with precision rapid prototypes are widely used in various fields, and various industries have higher and higher requirements for them. Not only require good-looking surface, but also higher quality. That's also what we're working towards.

We strive to exceed our customers' expectation in all aspects of product manufacturing process, and keep adopting advanced production facilities to improve efficiency and machining accuracy, to ensure high and stable quality, in parallel, further improve the cost-effective for our rapid prototypes. Besides, we can offer a one-stop service to fulfill your whole project.

*More Professional Turning Milling Anodized Parts for reference

Our service process and advantages

Comparing to other manufacturer , we can offer the following:

*Competitive Price

*Good Service

*Rich Experience

*Perfect Quality

HC-Rapidprototype Advantage and Service

- Rapid prototyping capabilities for quick turnaround: Leveraging advanced 3D printing and machining technologies, our rapid prototyping services ensure swift production. We streamline processes to deliver functional prototypes in record time, accelerating your product development cycle.

- Design assistance to optimize your parts for manufacturability: Our team of experienced engineers offers expert design assistance. By analyzing your part designs, we identify potential manufacturing issues and suggest improvements to enhance efficiency, reduce costs, and ensure smooth production.

- Comprehensive quality assurance processes: From raw material inspection to final product testing, our multi - stage quality assurance processes leave no room for error. Rigorous checks at every step guarantee that all products meet the highest quality standards.

- On-time delivery commitment: We understand the importance of deadlines. With efficient project management and a dedicated production team, we are committed to delivering your orders on time, every time, ensuring your projects stay on schedule.

Product Characteristics

Our Professional Turning and Milling Anodized Parts offer:

- Enhanced corrosion resistance

- Improved wear resistance

- Aesthetic appeal with various color options

- Excellent dimensional stability

Production Process

- CAD/CAM design and optimization: Our skilled designers use advanced CAD/CAM software to create detailed designs, then optimize them for efficient manufacturing, ensuring seamless integration with production processes.

- CNC turning and milling: Employing state - of - the - art CNC machines, we perform turning and milling operations with high precision, accurately shaping materials into complex parts according to specifications.

- Precision measurement and inspection: Equipped with sophisticated measuring tools, our technicians conduct meticulous inspections, verifying dimensions and tolerances to ensure parts meet strict quality requirements.

- Anodizing treatment: We offer professional anodizing treatment, which not only enhances the corrosion resistance of parts but also improves their appearance and durability through an electrochemical process.

- Final quality control and packaging: Before shipping, our team conducts a final quality check to confirm product excellence. Parts are then carefully packaged to prevent damage during transportation and delivery.

Applications

Our anodized parts find use in diverse industries:

- Aerospace components

- Automotive systems

- Medical device manufacturing

- Electronics housing

- Industrial machinery

Packing and shipping remark

1. Carton for outer packing, inner packaging according to customer’s requirement.

2. Shipping: Support Express, Sea freight, Land freight and Air freight.

3. Any questions, please kindly contact us. Our team will try our best to offer you the good quality and best service.

FAQs

Q. How long does the product cycle take?

A: This requires our engineering to calculate and negotiate with you each other.

Q. Will I know the production plan of the product?

A: Of course, we will tell you every production cycle.

Q: What is the minimum order quantity for Professional Turning and Milling Anodized Parts?

A: We accommodate various order sizes, from prototypes to large production runs. Contact us for a custom quote.

Q: Can you provide custom anodizing colors?

A: Yes, we offer a wide range of anodizing colors to match your branding or functional requirements.

YOU MAY LIKE

_1744788508965.png)