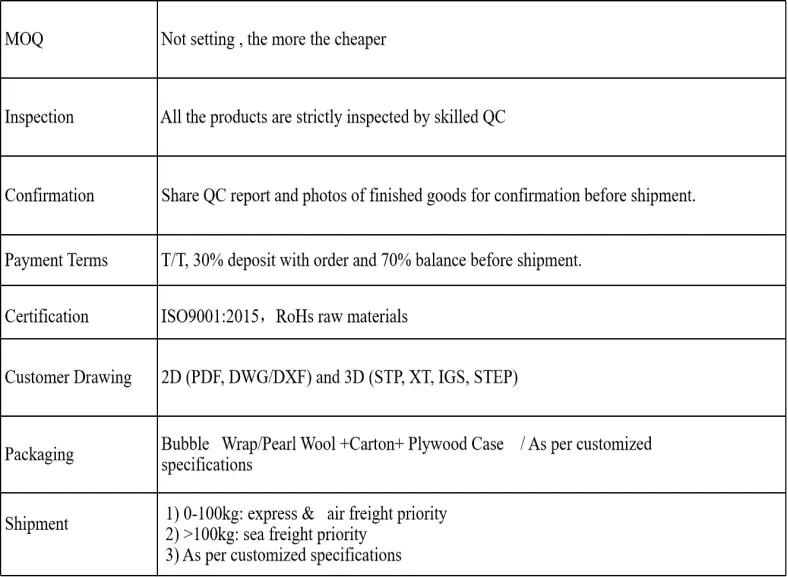

Delivery terms

More Medium Speed Wire Cutting Parts for reference

Introduction

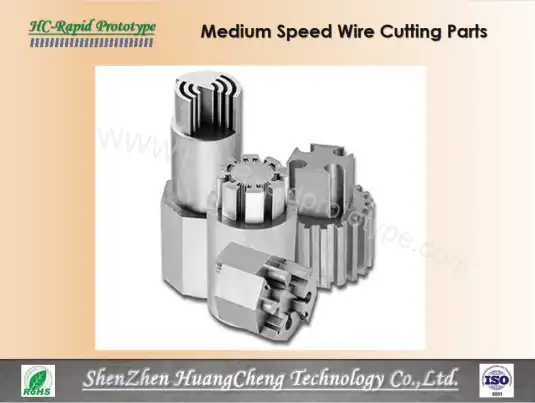

Medium Speed Wire Cutting Parts is categorized under reciprocating high - speed wire EDM (Electrical Discharge Machining) machine tools. It innovatively endows high - speed reciprocating wire EDM machines with multiple cutting functions. Contrary to what the name might suggest, "medium wire cutting" doesn't refer to a wire cutting speed situated between high and low speeds. Instead, it represents a composite wire cutting process. During rough machining, it employs the principle of high - speed wire feeding, with speeds ranging from 8 - 12m/s, enabling rapid material removal. For finishing operations, low - speed wire feeding at 1 - 3m/s is utilized. This two - stage approach ensures the workpiece remains relatively stable with minimal jitter. By performing multiple cuts, it effectively mitigates errors caused by material deformation and molybdenum wire loss. As a result, the processing quality achieved by Medium Speed Wire Cutting lies between that of high - speed and low - speed wire feeders, offering a balance of efficiency and precision for a wide range of machining applications.

Application

- This machining method is extensively utilized in the fabrication of diverse punching dies. Its versatility allows it to handle a wide range of die designs, ensuring high - precision and durable results that meet the stringent requirements of the manufacturing industry.

- Capable of processing micro - shaped holes, narrow slits, and workpieces with intricate geometries, it excels in creating detailed and complex components. This makes it an ideal choice for industries that demand high - precision parts with unique shapes.

- For machining templates and forming tools, this technique offers excellent accuracy and consistency. It can produce tools that are essential for various manufacturing processes, ensuring the quality and efficiency of production lines.

- It is highly effective in processing powder metallurgy molds, inlaid cavity molds, wire drawing molds, and corrugated plate forming molds. Each mold type requires specific machining precision, which this method can reliably deliver.

- When it comes to machining hard materials, cutting thin slices, or working with precious metal materials, this process provides the necessary control and precision. It minimizes material waste and ensures the integrity of valuable materials during processing.

- Specialized in machining cams and unique gears, it can accurately create components with specific profiles and tooth geometries. These parts are crucial for the proper functioning of many mechanical systems.

- Well - suited for the production of small - batch, multi - variety parts, it significantly reduces mold - making costs. By shortening the production cycle, it enables businesses to respond quickly to market demands and reduce time - to - market.

- It can be employed to process material test samples, various types of holes, and complex - shaped parts made from high - hardness materials. This makes it a valuable asset in quality control and research and development settings.

- This machining process is adept at creating microstructures, special - shaped grooves, and standard defects. These features are important in applications such as microelectronics and quality assessment of materials.

- During new product trials, parts can be directly cut from the blank, eliminating the need for extensive pre - processing. This streamlines the prototyping process and speeds up the development of new products.

- When dealing with thin parts, the ability to stack multiple pieces for processing increases efficiency. It ensures consistent machining quality across all parts while reducing overall production time.

HC-Rapidprototype Advantage:

- Advanced CNC machining centers for precise manufacturing

- Rigorous quality control throughout the production process

- Quick response time and on-time delivery

- Customization options to suit your specific requirements

Product Characteristics:

- High precision and stability

- Excellent surface finish

- Long service life

- Compatible with most Medium Speed Wire Cutting Parts

Shipping

FAQs

Q1: Where is your factory?

A1: We are located in Shen zhen, China.

Q2: Can you provide one-stop service including of material, processing, finish, assembly etc.?

A2: Yes, we can.

YOU MAY LIKE

_1744788508965.png)