Product Details:

Material: aluminum

Surface Treatment: anodized

Processing Method: CNC machining, CNC milling, drilling, Tapping.

Application Industry: Industrial manufacturing

Tolerance: ISO 2768-m, or according to client's drawings request.

Delivery time: 8-10 working days.

Introduction:

CNC turning can produce accurate diameter and reasonable machining depth, so as to obtain good overall machining accuracy. High Quality CNC Turning Anodizing Parts used for various industries, HC-Rapidprototype are ISO 9001:2015 certificated factory, providing CNC machining service, precision machining, CNC turning, CNC milling service over 10 years, we have enough capability to do your prototypes well , Welcome to contact for long-term cooperation.

CNC turning process:

- The High Quality CNC Turning Anodizing Parts process feasibility study meticulously examines design drawings and related technical documents. By analyzing part geometries and requirements, it determines the most suitable machining methods to ensure efficient and accurate production.

- Selecting the type of CNC machine tools and their specifications involves evaluating factors like part size, complexity, and production volume. This ensures the chosen equipment can handle the machining tasks with precision and productivity.

- Choosing the fixture and its supporting tools is crucial for securing the workpiece during machining. Proper selection guarantees stability, reduces vibrations, and enables consistent and accurate machining results.

- The selection of the tool and tool clamping system focuses on matching the machining operations and material properties. It ensures optimal cutting performance, tool life, and surface finish of the machined parts.

- CNC machining programs and process planning map out the entire machining sequence. They define toolpaths, cutting parameters, and operation steps to guide the CNC machine in producing parts that meet the design requirements.

- Determining the processing area involves identifying the regions on the workpiece that need machining. This helps in optimizing toolpaths, reducing machining time, and ensuring all necessary features are processed accurately.

- The design of CNC machining process content details each machining operation, including the type of cut, feed rate, and depth of cut. It provides a comprehensive guide for the machining process to achieve the desired part quality.

- Coding CNC programs translates the process plan into machine - readable instructions. Skilled programmers use specialized software to write precise code that controls the CNC machine's movements and operations.

- NC program debugging and process validation test the CNC program and machining process. This step detects and corrects any errors or inefficiencies, ensuring the program runs smoothly and produces parts within the specified tolerances.

- Finally, all the NC process files are completed, including programs, process plans, and documentation. These are then archived for future reference, enabling traceability and facilitating continuous improvement in the machining process.

HC-Rapidprototype Advantage and Service:

- State-of-the-art CNC turning centers for precision machining

- In-house anodizing facilities for quality control

- Rapid prototyping and bulk production capabilities

- Expert engineering support for design optimization

- Strict quality control measures throughout production

Product Characteristics:

- Superior corrosion resistance

- Enhanced wear resistance

- Improved electrical insulation

- Aesthetically pleasing finish

- Consistent quality across large production runs

Applications:

Our High Quality CNC Turning Anodizing Parts find applications in:

- Aerospace components

- Automotive industry parts

- Medical device manufacturing

- Electronics housing and components

- Industrial machinery elements

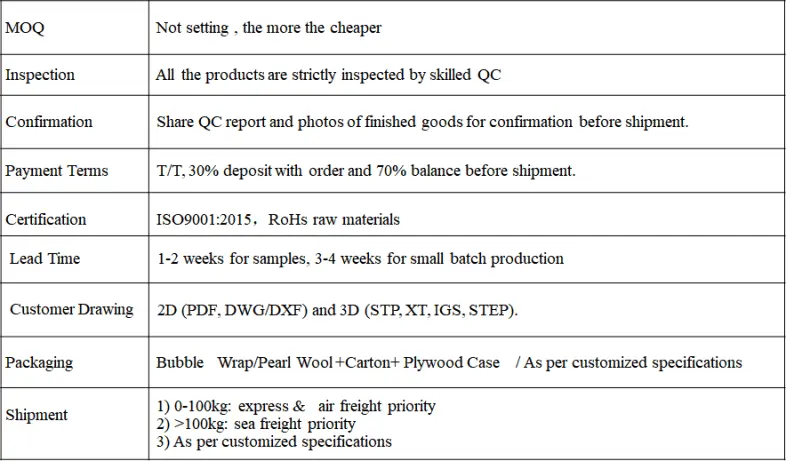

Delivery Terms:

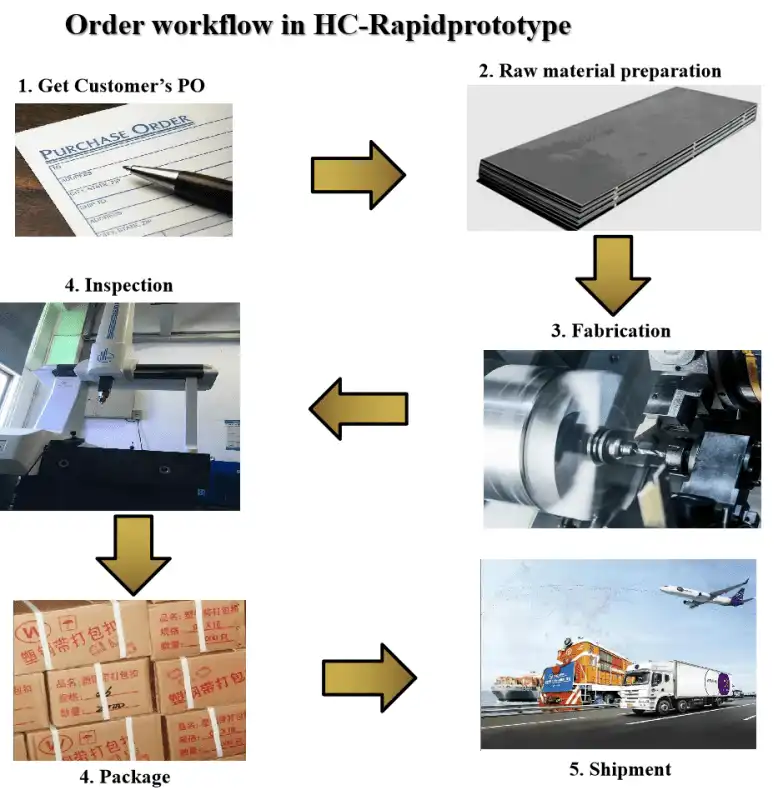

HC workflow for new order:

FAQs:

Q1: How to deal with the parts received when they are found to be in poor quality?

A1: Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non-conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time, the resulting transportation costs borne by our company.

Q2: Do you provide custom packaging?

A2: Yes, we can do it for you.

YOU MAY LIKE

_1744788508965.png)