High Speed Wire Cutting Parts: Precision Engineering Solutions

ShenZhenHuangCheng Technology Co.,Ltd. is a leading manufacturer and supplier of High Speed Wire Cutting Parts. Our advanced equipment and comprehensive facilities ensure top-quality products. We pride ourselves on efficient service, quick response times, and on-time delivery of precision-engineered parts that meet the highest industry standards.

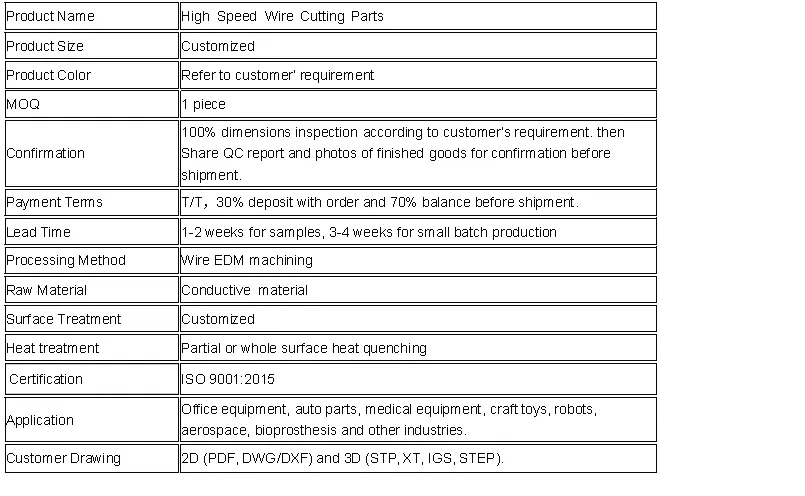

Product Details

Introduction

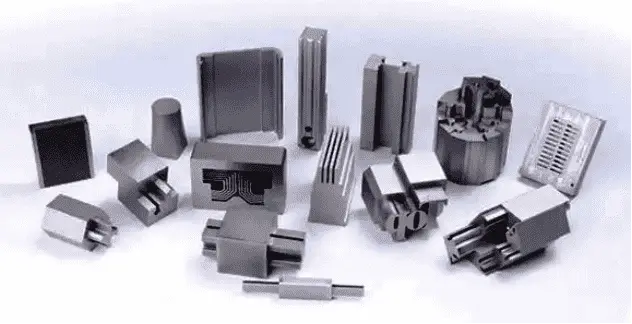

High Speed Wire Cutting Part is a kind of WEDM, Its characteristics and processing conditions can be summarized as following :

- One significant advantage is the elimination of the need to produce complex - shaped tool electrodes. This machining method enables the processing of two - dimensional curved surfaces with a straight line as the generatrix, simplifying the manufacturing process and reducing both time and cost associated with electrode production.

- It has the remarkable capability to cut extremely narrow slits, approximately 0.05mm in width. This precision allows for the creation of intricate and detailed parts, making it an ideal choice for applications that demand high - accuracy micro - machining.

- During the machining process, excess materials are not transformed into waste chips. Instead, they can be reused or remain intact, which greatly enhances the utilization rate of energy and materials. This sustainable approach not only saves resources but also reduces environmental impact.

- In low - speed wire EDM machine tools where the electrode wire is non - recyclable, the continuous renewal of the electrode wire plays a crucial role. It helps to improve machining accuracy by ensuring a fresh and consistent cutting edge, while also reducing the surface roughness of the processed workpiece for a better finish.

Characteristic

The characteristic of fast-moving wire is that molybdenum wire is used as the wire core, and the electrode can be used many times, but the precision and surface roughness are low, The processed things are simple, rough, and the cost is low.

- Superior conductivity is a key feature that significantly enhances the High Speed Wire Cutting Parts. It enables efficient electrical discharge, allowing for faster material removal and smoother cuts, thereby optimizing the overall machining process.

- The high tensile strength of the wire ensures it can withstand the rigors of the cutting process, greatly reducing the likelihood of wire breakage. This reliability minimizes downtime and boosts productivity.

- Excellent straightness is crucial for achieving precise cuts. It prevents deviations during the cutting operation, ensuring that the workpiece is machined to exact specifications and enhancing the overall cutting accuracy.

- A consistent diameter throughout the wire guarantees uniform cutting results. This consistency eliminates variations in cut quality, ensuring that each workpiece meets the same high - quality standards.

HC-Rapidprototype Advantage and Service:

- Customization options to meet specific requirements offer the flexibility to tailor products precisely to your needs. Our team works closely with you, from material selection to design adjustments, ensuring the final product aligns perfectly with your unique specifications.

- Rapid prototyping capabilities for quick turnaround leverage advanced technologies to swiftly transform your concepts into physical models. This enables rapid design validation and iteration, reducing the time from idea to marketable product significantly.

- Comprehensive quality control measures are implemented at every stage of production. From raw material inspection to final product testing, multiple checks ensure that all items meet or exceed the highest industry standards, guaranteeing consistent quality.

- Expert technical support and consultation are available throughout your project. Our experienced professionals provide valuable insights, troubleshoot issues, and offer guidance, ensuring a smooth process and successful outcomes for your endeavors.

Remark

- We prioritize customer satisfaction in our packaging approach. For inner packaging, we can fully comply with your specific requirements, whether it's using special materials for protection or custom - designed inserts. The outer packing typically consists of sturdy normal cartons, ensuring the safety of your products during transit.

- When it comes to shipping, we provide a wide range of options to suit your needs. Our services support Express for urgent deliveries, Sea freight for large - volume and cost - effective shipments, Land freight for regional transportation, and Air freight for fast - paced international deliveries.

- Should you have any questions or concerns, please don't hesitate to reach out to us. Our dedicated team is committed to offering you top - notch products in terms of quality and providing the best service possible, ensuring a seamless experience throughout your order process.

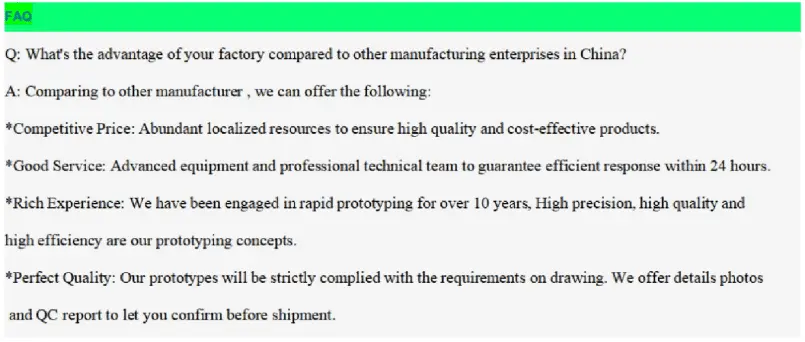

FAQ

YOU MAY LIKE

_1744788508965.png)