Product Parameter:

Material: aluminum, carbon steel, alloy steel, plastic,tool steel.

Surface Treatment: Silver anodized, Hard anodizing, Oxide black, Zinc-plated

Processing Method: NC turning, Lathe machining, CNC milling.

Application Industry: Precision tools, Lathe fixtures ,Jigs and Fixtures

Tolerance: ISO2768-m or refer to customer's request

Delivery time: 5-15 working days. depending on the volume.

Introduction:

HC-Rapidprototype is ISO9001: 2015 certificated company and good at design and manufacture all kinds of Jigs and Fixtures, Jig tools, lather fixtures .The Lathe Machine CNC Turning Machining Parts main used material are aluminum, carbon steel, alloy steel, plastic.etc. We produced them by turning, milling, CNC machining.Welcome to contact us for future long cooperation.

Industries We Serve:

Our Lathe Machine CNC Turning Machining Parts are trusted by global manufacturers in:

- Automotive: In the automotive industry, we manufacture crucial engine components that enhance power and efficiency, highly sensitive sensors for accurate vehicle monitoring, and durable transmission parts ensuring smooth gear shifts.

- Aerospace: For the aerospace sector, our offerings include precision - made bushings, reliable fittings, and essential hydraulic system components, all engineered to meet strict aviation standards and endure extreme conditions.

- Electronics: In electronics manufacturing, we produce effective heat sinks to manage thermal issues, high - quality connectors for stable electrical connections, and robust housings to protect internal circuitry.

- Industrial Machinery: When it comes to industrial machinery, we create sturdy shafts, precisely - cut gears, and durable valve bodies, which are vital for the smooth and efficient operation of various industrial equipment.

End-to-End Production Process:

- Design Review: Engage in close collaboration with our team of seasoned engineers during the Design Review phase. Together, we will meticulously refine your CAD models, optimizing them for manufacturability and ensuring they meet your exact specifications.

- Material Selection: Benefit from our extensive inventory of certified raw materials during the Material Selection process. With a diverse range of options at your disposal, you can choose the perfect material to suit your project's unique requirements and performance needs.

- Machining: Our Machining services encompass a comprehensive suite of operations, including precise CNC turning, milling, and finishing processes. Leveraging advanced equipment and techniques, we guarantee high - quality parts with tight tolerances and excellent surface finishes.

- Quality Control: Our rigorous Quality Control measures involve state - of - the - art 3D scanning, accurate hardness testing, and meticulous dimensional verification. This multi - step approach ensures that every product leaving our facility meets the highest quality standards.

- Packaging & Delivery: We take great care in Packaging & Delivery, using anti - rust materials to protect your products during transit. Additionally, we offer real - time shipment tracking, allowing you to monitor the progress of your order from our facility to your doorstep.

Why Choose ShenZhenHuangCheng?

- Cost-Effective: Our cost - effectiveness stems from strategic local material sourcing, which cuts down on transportation expenses, and lean manufacturing principles. These practices streamline production, eliminating waste and reducing costs by 15–20%, offering you high - quality products at competitive prices.

- Technical Support: We provide comprehensive technical support with dedicated account managers who understand your unique needs. Additionally, our post - purchase rework services ensure that any issues are promptly addressed, guaranteeing your satisfaction long after the sale.

- Global Reach: Boasting an extensive global reach, we have rich experience in serving clients across the globe. Our portfolio includes satisfied customers in Germany, the U.S., Japan, and many other countries, demonstrating our ability to meet diverse international standards and demands.

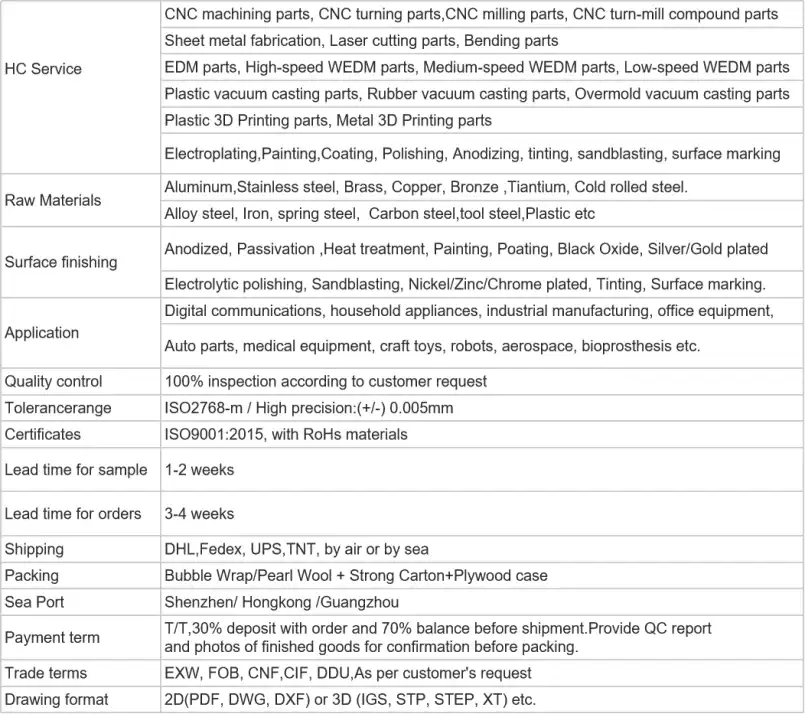

HC-Rapidprototype Capbility:

FAQs:

Q1: How to place an order to you?

A1: By email.

Q2: Do you provide weekly report for my orders?

A2: Yes, we do. and you can contact us for the status at any time.

Q3: How you guarantee the quality?

A3: Our Lathe Machine CNC Turning Machining Parts will be strictly complied with the requirements on drawing. We offer details photos and QC report to

let you confirm before shipment.

YOU MAY LIKE

_1744788508965.png)